DESIGN TO DELINEARIZE

The systems and processes associated with 'design to delinearise' are in place to provide designers with viable, proven solutions to the linear model - while still allowing for creativity-led and high quality designs. By learning about circular processes, you can make informed choices as to materials, production processes and even the structure of your business model - resulting in lowered greenhouse gas emissions and a more efficient use of natural resources.

AUTHORS: Alpha Barratt, Carolyn Edmondson, Yonah Huttenbach, Cheng Phukan, Raphaelle Vavasseur, Marjory Wilson

CONTEXT

The majority of the fashion industry has a linear approach to design. This ‘take-make-waste’ system has no consideration for waste produced during the design phase or end of life processes. Waste in the design phase is treated as an economic issue, rather than an environmental one, and the systems in place are only there to make sure money is not lost when fabric or other assets are wasted.

Author's own, adapted from Primark (2023)

The Circular Economy podcast talks to experts and insiders, and explores all aspects of the circular economy.

These episodes are particularly interesting:

Episode 103 - The role of design in the circular economy

Episode 106 - Busting the myths of circular design for fashion

Or check out the full list here.

If you’re a visual learner, why not try an episode of The Circular Fashion Show on Youtube? Another gem from the Ellen Macarthur Foundation, specifically focussed on the fashion industry.

The earliest examples of clothing were zero-waste (e.g. animal skins utilized in the shape they appear when removed from the animal)

Overtime, two separate developments occurred in garment cutting.

1. Those based on the shapes of animal skins.

2. Those which took the rectilinear shape of the loom as their starting point (paving the way for pattern cutting as an artform)

HISTORY

The earliest examples of clothing were zero-waste (e.g. animal skins utilized in the shape they appear when removed from the animal)

Overtime, two separate developments occurred in garment cutting. 1. Those based on the shapes of animal skins. 2. Those which took the rectilinear shape of the loom as their starting point (paving the way for pattern cutting as an artform)

Photo by Tima Miroshnichenko on Pexels.com

Zero waste garment construction can be found as early as 3000 BCE (Indian Saree).

Zero waste construction techniques from the Eastern Hemisphere set the precedent for modern day zero waste pattern cutting and it’s important to note the adoption and adaptation of these techniques in the modern European fashion context. Please see “DESIGN TO DECOLONIZE” section for further info.

Although the terminology is fairly new, the concept of repurposing, recycling and upcycling has been around for millenia, in many different cultures.

Repurposing in a specifically fashion context can be dated back to the 19th century - with Queen Victoria & Frederick Worth both utilizing the concept.

Recycling of garments can be traced as far back as the 1700’s during the Napoleonic War.

William McDonough and Michael Braungart popularized the terms Cradle to Cradle and Upcycling with their seminal book ‘Cradle to Cradle: Remaking the Way We Make Things’ (2002)

If you are interested in a deeper understanding of the history of designing to delinearise, follow this link for a downloadable PDF.

Photo by KUBAI KOIGI (2016)

DELINEARIZATION: A SYSTEMATIC APPROACH

HOW THE DESIGN PHASE AFFECTS THE CIRCULARITY OF PRODUCTS?

In order for products to successfully be circulated in either the biological or the technical cycle, it is essential they have been designed with their eventual circulation in mind. There are many products in our current economy that cannot be circulated in either cycle and end up as waste.

There are products that fuse technical and biological materials in such a way that we can’t separate them and circulate them – for example, textiles that blend natural and plastic fibres.

If designers thought about how their product could fit into the technical or biological cycles after use, that product could be made with that onward path in mind.

DELINEARIZATION: A SYSTEMATIC APPROACH

CIRCULATION OF PRODUCTS AND MATERIALS

The most effective way of retaining the value of products is to maintain and reuse them. So the first steps in the technical cycle are focused on keeping products whole to retain the maximum possible value. This could include business models based on sharing, so users get access to a product rather than owning it and more people get to use it over time. It could involve reuse through resale. It could mean cycles of maintenance, repair, and refurbishment.

The second principle of the circular economy is to circulate products and materials at their highest value. This means keeping materials in use, either as a product or, when that can no longer be used, as components or raw materials. This way, nothing becomes waste and the intrinsic value of products and materials are retained.

The circular economy system diagram, also known as the Butterfly Diagram, illustrates the continuous flow of materials in the circular economy. It consists of two main cycles – the technical cycle and the biological cycle.

THE BUTTERFLY DIAGRAM

There are a number of ways products and materials can be kept in circulation and it is helpful to think these two fundamental cycles – the technical cycle and the biological cycle.

These cycles allows the land to regenerate the nutrients, which can then be used to create new biodegradable materials, thus, ensuring the continuation of the cycle.

TECHNICAL CYCLE

In the technical cycle, products are kept in circulation in the economy through reuse, repair, remanufacturing, and recycling. This way, materials are kept in use and do not become waste. In the biological cycle, biodegradable materials are returned to the Earth and decomposed through processes such as composting and anaerobic digestion.

THE BIOLOGICAL CYCLE

Biodegradable materials that cannot be reused, like some food byproducts, can be circulated back into the economy in the biological cycle. By composting or anaerobically digesting organic materials, valuable nutrients, such as nitrogen, phosphorus, potassium, and micronutrients, can be used to help regenerate the land so we can grow more food or renewable materials like cotton and wood.

Cascading maximizes resource effectiveness by using biomass in products that create the most economic value over multiple lifetimes. This approach to production and consumption incorporates the idea that energy recovery should be a last resort and only employed after all higher-value approaches to retaining products and services have been exhausted. When products or materials can no longer be reused (cascaded), they move towards the outer loops of the biological cycle.

CASCADES

CIRCULAR BUSINESS MODEL & CIRCULAR DESIGN

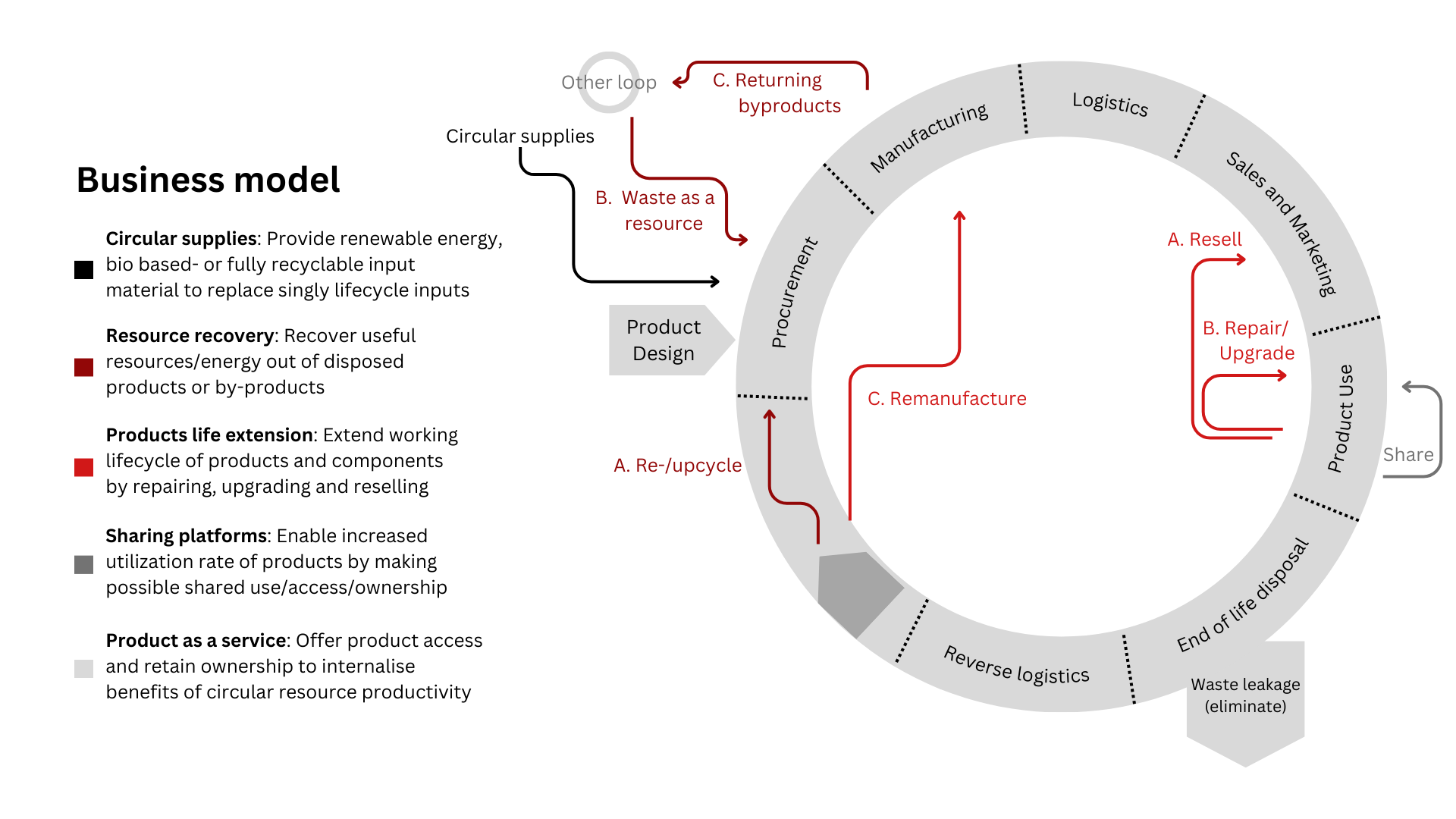

Author's own, adapted from Accenture (2020)

A circular business model articulates the logic of how an organization creates, delivers, and captures value to its broader range of stakeholders while minimizing ecological and social costs.For the fashion and apparel industry to operate within the planetary boundaries, it will be necessary to shift to circular business models that decouple economic activity from the use of virgin materials and other resources. To achieve this, it will be necessary to break away from linear ways of doing business, and to boost the economic rationale for product longevity, reuse, repair and recycling.

MAIN 5 CIRCULAR BUSINESS MODELS & ANALYSIS

PRODUCT

AS A SERVICE

Through a Product as a Service Business Model customers use products through a lease or pay-for-use arrangement versus the conventional buy-to-own approach. This model is attractive for companies that have high operational costs and ability to manage maintenance of that service and recapture residual value at the end of life.

RECOVERING AND RECYCLING

The resource recovery business model leverages technological innovations and capabilities to recover and reuse resource outputs that eliminates material leakage and maximizes economic value. Examples include closed loop recycling, industrial symbiosis and Cradle-to-Cradle designs, whereby waste materials are re-processed into new resources.

PRODUCT

AS A SERVICE

The sharing platform model is centered on the sharing of products and assets that have a low ownership or use rate. Companies that leverage this model can maximize the use of the products they sell, enhance productivity and value creation.

PRODUCT-LIFE-EXTENSION

The product life extension model helps companies extend the life cycle of their products and assets to ensure they remain economically useful. Material that otherwise would be wasted is maintained or even improved, such as through remanufacturing, repairing, upgrading or re-marketing. By extending the lifespan of the product for as long as possible, companies can keep material out of the landfill and discover new sources of revenue.

RESOURCE EFFICIENCY AND RECYCLING

The circular supplies business model is particularly relevant for companies dealing with scarce commodities, in which scarce resources are replaced with fully renewable, recyclable or biodegradable resource inputs.

Understanding the circular business models can help designers Develop or redefine the business model from a circular design perspective. It allows them to capture the value for customers, key partnerships, resources, and distribution models. Expand your perspective to the wider system and set your business up for success in an interconnected world.

Designing for circular business models in mind underpins all three circular economy principles mentioned in the previous sections. Eliminate Waste and Pollution, Circulte Products and Materials and Regenerating Nature. Most products are designed for a linear economy which means everything needs to be redesigned in accordance with the principles of the circular economy. There is not a single way to design a product or service that creates no waste and pollution or a business model that keeps products in use for years. Therefore, the principles are rather a guidance but the strategies and the execution can and will differ from case to case. The Design Strategies will therefore be introduced more in-depth on the following sections.

THE 9R’S

ORDER OF PRIORITY (HIGH TO LOW)

Refuse - Make the product redundant by abandoning its function or by offering the same function with a radically different product

Rethink - Make the product use more intensive (e.g. by sharing the product)

Reduce - Increase efficiency in product manufacture or use by consuming fewer natural resources and materials

Reuse - Reuse by another consumer (e.g. through purchasing second-hand) of a discarded product which is still in good condition and fulfills its original function

Repair - Repair and maintenance of a defective product so it can be used with its original function

Refurbish - Restore an old product and bring it up to date

Remanufacture - Use parts of discarded product in a new product with the same function

Repurpose - Use discarded product or its parts in a new product with a different function

Recycling - Processing materials to obtain the same grade of quality as the original material. In textiles, there are 2 main recycling methods - mechanical and chemical. For further information, click here

DESIGN STRATEGIES & APPROACHES

DESIGN FOR DURABILITY

MADE TO BE USED MORE

A key component of cyclical fashion is making things that can survive wear and tear and last for longer. Designers can make goods that are less likely to go out of style by focusing on timeless designs and using high-quality materials. Learn more about the technology and processes applied on this strategy by downloading our free PDF below.

BEST PRACTICES:

A quality rating system is designed with ecological footprint in mind. They have developed a strict scoring system to measure the physical durability of each item they produce. With computer modelling, including equations and analytics, they assess 100% of the line, and with a high level of objectivity.

A holistic approach to designing for durability by focusing on designing based on user feedback, educating on garment care and also focusing on 'emotional durability' which is encouraging customers to value and see value in their clothes more long term.

DESIGN FOR PRODUCT LIFE EXTENSION

MADE TO BE USED MORE

By including features that make it simple to repair or update a product, designers can make it last longer. This strategy can involve developing goods that can be readily disassembled and repaired, as well as using modular design, where components can be quickly upgraded or changed. Learn more about the technology and processes applied on this strategy by downloading our free PDF below.

BEST PRACTICES:

Provides building blocks such as detachable hoods, collars and liners to allow customers to embrace a modular wardrobe. This allows people to update elements of their garment without the need to completely replace it with a new garment in response to new trends each season. They're mission is that they are challenging the status quo by creating pieces that are designed to be enhanced, rather than replaced.

Every pair of Nudie Jeans comes with a lifetime of free repairs. They have repair spots worldwide in many major metropolitan cities. Offering free repairs allows for an easy way to extend the lifecycle of a product.

DESIGN FOR DISASSEMBLY

MADE TO BE MADE AGAIN

The product is made to be easily disassembled and separated into its various sections or components. Recycling and product repair are made simpler with this method. Learn more about the technology and processes applied on this strategy by downloading our free PDF below.

BEST PRACTICES:

An innovative startup that designed a new heat dissolvable stitching thread, enabling brands to transform their products into recyclable pieces from the manufacturing stage.

Completely modular, allowing each part to be reused and recycled into new parts. Instead of using glue, the shoe has pegs that slot into openings which also allows for easier and more efficient recycling.

DESIGN FOR RECYCLING

MADE TO BE MADE AGAIN

Learn more about the technology and processes applied on this strategy by downloading our free PDF below.Product makers can produce items that are simply disassembled into their constituent pieces and repurposed during production.

BEST PRACTICES:

Debuted the world’s first Cradle-to-Cradle Gold level certified t-shirt made entirely from organic cotton, including the thread and was treated with non-toxic dyes and chemicals allowing it to be recycled safely and efficiently.

FUTURECRAFT.LOOP a shoe that can be recycled from the outset, by using one material type (monocycle)and no glue.

DESIGN FOR UPCYCLING

MADE TO BE USED MORE

Learn more about the technology and processes applied on this strategy by downloading our free PDF below. This strategy focuses on creating goods that can be reused or altered to become something new or different.

BEST PRACTICES:

Currently one of the most successful upcycled commercial fashion brands on the market. Freitag upcycles discarded truck tarps into stylish new bags. They currently divert about 350 tons of truck tarps annually from landfill.

R/DONE upcycles old vintage Levis jeans into new items, since the company launch they have managed to divert 225,000 pairs of jeans from landfill. This brand sits in the luxury market and has been worn by countless international celebrities and figures.

DESIGN FOR ZERO WASTE

MADE FROM SAFE AND RECYCLED OR RENEWABLE INPUTS/LESS WASTE

A fundamental component of circular fashion is creating products that produce no waste. Designers can collaborate with factories and manufacturers to lower their waste production and adopt pattern-making methods that produce the least amount of trash, such as zero-waste pattern cutting. Learn more about the technology and processes applied on this strategy by downloading our free PDF below.

BEST PRACTICES:

Innovative use of rectangular patterns drastically minimizes textile waste. The brand’s signature two-fold purpose was developed with the wearer and the environment in mind. By using rectangular patterns and specialized sewing techniques, the label significantly reduces its amount of textile waste of 15-20% waste rate compared to the industry standard of 30%.

Wrote the book ‘Zero Waste Fashion Design’, written by two industry leading pioneers, Timo Rissanen and Holly McQuillan, the book offers flexible strategies and easy-to-master zero waste techniques.

DESIGN FOR BIOMICICRY

MADE FROM SAFE AND RECYCLED OR RENEWABLE INPUTS/LESS WASTE

Designing systems and products that mirror circular, naturally occurring processes is known as biomimicry. Designers can take their cues from nature to produce goods that are effective, long-lasting, and waste-free. Learn more about the technology and processes applied on this strategy by downloading our free PDF below.

BEST PRACTICES:

Mycoworks uses mycelium’s natural capacity to transform plant matter into its own biomass, creating high-value materials from byproducts from the agriculture and lumber industries. Using mycelium can deliver a more efficient process that minimizes waste, creates unprecedented design possibilities, and meets the exact specifications of its brand partners. This allows for the customization of fabric factors like strength, thickness, weight, shape, and drape.

Studied how Spiders turn proteins into silk, inspiring a technology to produce a sustainable silk alternative. Research is being conducted on how this can be used by the military for parachutes and bulletproof vests due the extreme tactile strength.

METHODS

SUPPORTING METHODS AND TECHNOLOGIES:

PRODUCT LIFECYCLE STAGES:

Raw Material Acquisition: This stage involves the extraction or harvesting of raw materials, such as mining ores or cutting down trees.

Manufacturing: The raw materials are transformed into the final product through various manufacturing processes, including processing, assembly, and packaging.

Distribution: The product is transported from the manufacturing facility to the end-user or retailer, which includes transportation by road, rail, sea, or air.

Use and End-of-Life: The product is utilized by the consumer during its useful life, and eventually, it reaches the end of its life cycle. This stage includes product maintenance, energy consumption during use, and the final disposal or recycling of the product.

Digital product passports and Blockchain Technology: Blockchain can enhance traceability and transparency in waste management by creating a secure and immutable record of waste transactions. It can help track the movement of waste materials, validate recycling and disposal processes

Product LCA: Product LCA provides a comprehensive understanding of a product's environmental footprint, enabling companies and stakeholders to make informed decisions and develop more sustainable products and processes.